This page is under development.

Introduction

This webpage is unique in that it combines information on the many types of fasteners with information on how to determine their strengths. This extends to joint strengths as well since the parts being fastened together are often weaker than the fastener itself. This is especially true when the objects are relatively thin sheets of metal, a common occurance in aircraft.The page begins by reviewing the many fastener categories, focusing on those used in the American aircraft industry. It progresses to........., and concludes with fastener and joint strength analysis methods.

The Difference Between a Bolt and a Screw

A bolt is designed to be inserted through a smooth hole and secured with a nut, while a screw is designed to be used in a threaded hole—sometimes along with a nut. To learn more, see the American Society of Mechanical Engineers (ASME) standard B18.2.1 (1996).Fastener Standards

| AN | - | Air Force / Navy Standards |

| NAS | - | National Aerospace Standards |

| MS | - | Military Standards |

| AMS | - | Aeronautical Material Specifications |

| SAE | - | Society of Automotive Engineers |

| MIL | - | Military Specifications |

Types of Fasteners

|

|

|

|

|

Wood Screws Screws with a smooth shank and tapered point for use in wood. Abbreviated WS |

Sheet Metal Screws Fully threaded screws with a point for use in sheet metal. Abbreviated SMS |

Machine Screws Screws with threads for use with a nut or tapped hole. Abbreviated MS |

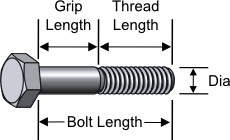

Hex Bolts Bolts with a hexagonal head with threads for use with a nut or tapped hole. Abbreviated HHMB or HXBT |

|

|

|

|

|

Carriage Bolts |

Lag Bolts Bolts with a wood thread and pointed tip. Abbreviated Lag |

Eye Bolts A bolt with a circular ring on the head end. Used for attaching rope or chain. |

Eye Lags Similar to an eye bolt but with wood threads instead of machine thread. |

|

|

||

|

U-Bolts Bolts in U shape for attaching to pipe or other round surfaces. Also available with a square bend. |

J-Bolts J shaped bolts are used for tie-downs or as an open eye bolt. |

Head Styles

|

|

|

|

| Flat A countersunk head with a flat top. Abbreviated FH |

Oval A countersunk head with a rounded top. Abbreviated OH or OV |

Pan A slightly rounded head with short vertical sides. Abbreviated PN |

Truss |

|

|

|

|

| Round |

Hex A hexagonal Head. Abbreviated HH or HX |

Hex Washer A hex head with built in washer. |

Slotted Hex Washer A hex head with built in washer and a slot. |

|

|

||

Socket Cap |

Button A low profile rounded head using a socket drive. |

Tension Bolt Markings and Strength

Blah, Blah, Blah...| Head Marking | Grade and Material |

Nominal Size Range (inches) |

Mechanical Properties | ||

|---|---|---|---|---|---|

| Proof Load (psi) |

Min. Yield Strength (psi) |

Min. Tensile Strength (psi) |

|||

No Markings |

Grade 2Low or medium carbon steel |

1/4 thru 3/4 | 55,000 | 57,000 | 74,000 |

| >3/4 thru 1-1/2 | 33,000 | 36,000 | 60,000 | ||

3 Radial Lines |

Grade 5Medium Carbon Steel, Quenched and Tempered |

1/4 thru 1 | 85,000 | 92,000 | 120,000 |

| >1 thru 1-1/2 | 74,000 | 81,000 | 105,000 | ||

6 Radial Lines |

Grade 8Medium Carbon Alloy Steel, Quenched and Tempered |

1/4 thru 1-1/2 | 120,000 | 130,000 | 150,000 |

| Stainless markings vary. Most stainless is non-magnetic | 18-8 StainlessSteel alloy with 17-19% Chromium and 8-13% Nickel |

1/4 thru 5/8 | 40,000 Min. 80,000 – 90,000 Typical | 100,000 – 125,000 Typical | |

| 3/4 thru 1 | 40,000 Min. 45,000 – 70,000 Typical | 100,000 Typical | |||

| Above 1 | 80,000 – 90,000 Typical | ||||

|

Proof Load: Tensile load which the bolt must withstand without any evidence of permanent set. Yield Strength: Load at which the bolt exhibits a specific permanent deformation. Tensile Strength: Maximum tensile load which the bolt can withstand before breaking or failing. |

|||||

Theoretical Gauge Factor Values

It turns out that gauge factors can be estimated from the \(R = \rho L / A\) relationship by first determining \(dR/dL\) as followsAcknowledgements

Many photographs and sketches shown here were taken from the internet and found via Google searches. Each such image has been referenced in order to give credit to its source. I especially want to acknowledge www.boltdepot.com as a primary source of information here.Also, thanks very much to Chuck Boulware and Bill Dunmon for contributing to this page.